our products

We would like to inform you that our main clients are Limited Companies, Defence, food industries, pharmaceuticals, agriculture and confectionaries Departments in all over India and International. We further confirm that the customers continue to place an order with our good performance machinaries, which goes to prove the quality of the machines manufactured & marketed by us.

1. Non Silicon Defoamer :

Usage for preparation in/of Breweries fermendation exothermic reaction system. From 50 litres up to 5000 litres. Heating-Cooling to control the temperature at Exothermic Reaction.

Lab Sand Mill :

To process pilot batches and formulation in the recipe of chemical process. Available size- 2 litres up to 10 litres with coding jacket and agitator- grinding media- steatite/Glass beads/zirconium- Usage: Paint/Foods/Pharmaceuticals.

Planetary Mixer :

To process- bakery/Confectionaries/ Pharmaceuticals preparing pilot batches. Available size- 10 kg up to 500 kg SS304/316. 316L surgical grade- Exothermic and Concentric movements of blades.

Lab Model Reactor:

To formulate the pilot batch of process in the field of medicines chemical reaction with heating and cooling. With control panels to stimulate exothermic reaction- available size- 5 litres up to 20 litres.

Bomb testing equipment:

Custom built defence department field testing device. to test 90 and 120 mm field bombs especially made for defence departments at factory

Bead mill

High efficiency chemical processing machine 5000 litre process with grinding media.

Attritor :

Attritor mill for wet chemical milling for micron particles in the field of paint, pharmaceuticals and food industries. Available size from 50 litres up to 5000 litres capacity in SS 304/SS316 L surgical grade.

Attritor : (higher capacity)

Attritor mill for wet chemical milling in the field of paint,pharmaceuticals and food industries. At available size from 50 litres up to 5000 litres capacity in SS 304/SS316 L surgical grade for the process food industries partcles size reduction process available. surgical grade for the process of chemicals.

Pug Mixer:

To process- Powder putty water base/Tinker paste/Wall putty and multiple application in the chemical processing area- Available capacity- 50 kg up to 5000 kg- in M.S/SS304/SS316- depends the application/Formulation.

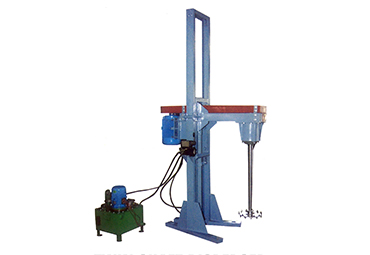

Twin Shaft Disperser:

To process wall putty nitrate cellulose process in the field of paint industries with High dispersion process area. Available size- 500 up to 5000 litres.

Variable speed mixer :

To process the chemicals paints, inks and connected dispersion required area with panel board, variable speed, Invertor for 100 to 1400 RPM. Controls available up to 15 HP.

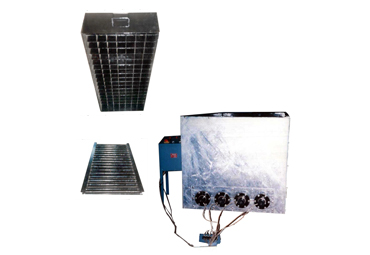

SS filters :

special type SS filters made in SS316/SS316L surgical grade for pharmaceutical processing filters before feed into reactors

Dyno mill :

Dynamically balanced high efficiency chemical milling equipment in the field of paint, pharmaceuticals, food, with cooling and heating system. Features available according to the process with chilling paint. Capacity- 1 to 1.5 litres/2 to 3 litres/5 to 7 litres per minute.

Sigma kneader :

High efficient in the kneading process of semi solid chemicals. Batch type in the field of food,ceramic,ink, pharmaceuticals,Rubber processing industry with cooling and heating jacketed in SS304/SS316/SS316L surgical grade available capacity 25 litres up to 3000 kgs with hydraulically tilting arrangements.

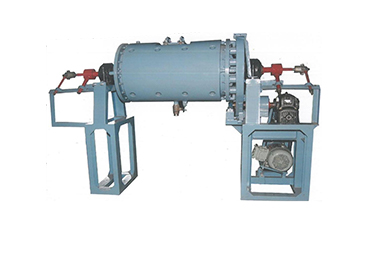

Ball mill- special type:

Made for aluminium paste manufacturing of paint with cooling jacket, pressure releaser design with efficient grinding with wet grinding and powder grinding. Standard type ball mill from 50 litres up to 5000 litres Batch type available for wet grading and powder grading with dust collector. Area of application: Food chemicals, Pharmaceuticals, powder preparation and particle size reduction.

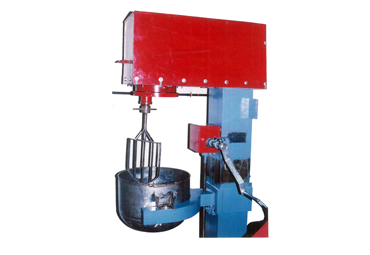

High speed disperser :

High efficiency dispersion equipment for paint/nitrate cellulose, ink manufacturing with jacked vessel portable type with hydraulically operated vertical movements- variable speed inverter for 50 to 1500 RPM panel board with corporate automation systems available from 15 hp up to 150 hp for high density and high products

Thinning vessels :

Made in SS304 grade with cooling jacket portable with stationary type to move with pallet truck with valves with lock,charging mouth,discharge at bottom with stopper product display holder-from 100 litres up to 2000 litres.

Triple roll mill :

Tripple rolls Mill for ink, paints, putty, heavy solids grinding in various capacity. 3 Rollers in chilled costing 6X12, 8X16, 12X24, 15X30, 20X40 with rollers hydraulic/manual. product collectors tray, pharmaceutical industry, homeopathy medicines process application.

Powder grinding ball mill :

Ball mill with shrouder for powder grinding in various capacities and applications.

WATER BASE PAINT MANUFACTURING PLANT :

water base paint and wet wall putty manufacturing plant with single platform with material handling lift.

Bead Mill with Flame proof :

Bead Mill with Flame proof drives in various capacities

Poly vinyl acetate reactor :

The binders manufacturing reactor usage of textile industries/paper products/ink industries process. Size available 100 litres up to 3000 litres in dispersion/heating/cooling with arrangements/reflex and control system for exothermic reaction.

Thermoplast paint manufacturing unit :

The Plant designed for road marking, Paint manufacturing unit with complete system and load facilities with dust collecting system incorporated top side of the vessal.

High speed disperser for bulk production :

The special Equipment designed and supplied to AMCOS XL PAINT PVT. LTD, Kanjikode, Kerala manufacture for enamal - 18000 litres per day production. The first stage process/grading at Attritor 2000 kg capacity within 30 to 45 minutes and discharge into the movable type vessels each 2000 litres capacity 3 numbers. The first vessel process dispersion with final make up lift the HSD and place the second vessel and third vessel.

Grinding Process details: Attritor grinding and discharge to first vessel for final make up the second batch of pigments and third vessel-after completion of process the discharge and packing will be carried out at bottom floor from the 3 vessels installed capacity is 18000 litres enamel paint per day-attritor HP -50 HP with HSD-60 HP with hydraulic-5 HP. Installed area-3000 square feet with complete assembly.